Hit enter to search or ESC to close

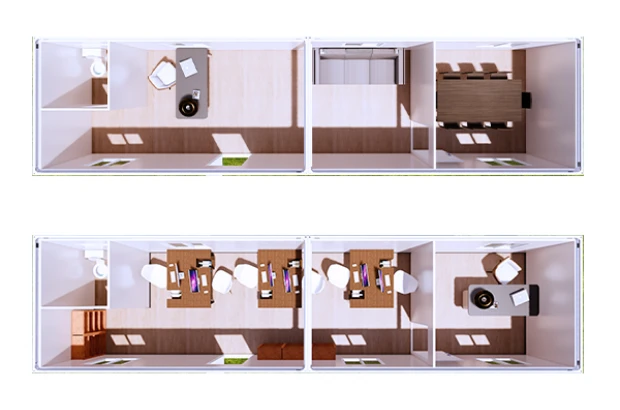

The talk of the trade shows lately is modular building solutions. To be honest, I’ve watched this category mature from scrappy “site cabins” into precision-engineered assets you can spec, ship, and assemble with surprising speed. The standout this season: the assemble container111 house—factory-built modules that click together on-site with less noise, less waste, and, frankly, fewer headaches.

Here’s the short version: demand is rising because developers want predictable timelines, facility managers want easier maintenance, and sustainability teams want lower embodied carbon. In fact, many customers say they’re switching after one brutal winter poured rain on their schedules and budgets. I get it.

Built in Suzhou (Fanxiang Village, Taoyuan Town, Wujiang District, to be precise), this system packages a galvanized steel frame with insulated sandwich panels, integrated MEP channels, and flooring options that don’t feel temporary. It’s not a magic box—just a well-engineered one. And that, in my view, is better.

| Parameter | Specification (≈, real-world use may vary) |

|---|---|

| Frame | Q235B galvanized steel, EN 1090-compliant fabrication |

| Wall/Roof Panels | EPS / Rockwool / PU sandwich panels, 50–100 mm, EN 14509 |

| Thermal | U-value ≈ 0.28–0.45 W/m²·K (panel-dependent) |

| Wind / Snow | Wind up to 0.6–0.75 kPa; snow 0.5–1.5 kPa (GB 50009 load paths) |

| Fire | Rockwool option up to A2-s1,d0; internal finishes Class B-s2,d0 |

| Size Options | 20-ft and 40-ft modules; stacking 2–3 stories with bracing |

| Assembly Time | ≈ 4–8 hours per unit with a 4-person crew and light equipment |

| Service Life | 20–25 years with routine maintenance (coating + sealant cycles) |

| Certifications | ISO 9001, ISO 14001; material tests per ISO 9227, EN 14509 |

Materials are laser-cut and welded, then hot-dip galvanized or powder coated. Panels are laminated under controlled pressure; edges sealed against capillary leaks. QC includes weld UT/VT checks, panel core density verification, air-leakage checks approximating ASTM E283, water-tightness spray tests, and random salt-spray per ISO 9227 on coated samples. Before shipping, modules are flat-packed and labeled; on site, crews bolt frames, drop panels, connect MEP, then perform insulation and earthing tests. It’s tidy work when the site is prepped—actually, that’s half the battle.

Feedback? One facilities manager told me, “We expected temporary—got solid.” Another noted HVAC loads dropped around 18–22% after switching to Rockwool cores. That tracks with the thermal data I’ve seen.

| Vendor | Origin | Lead Time | Customization | FOB Price | Warranty |

|---|---|---|---|---|---|

| ZN House (assemble container111 house) | Suzhou, China | 3–5 weeks | High (layout, panel core, facade) | ≈ $1,800–$3,600/unit | 5 years structure |

| Vendor A | EU | 5–8 weeks | Medium | ≈ $2,900–$5,200/unit | 10 years structure |

| Vendor B | MEA | 4–7 weeks | Medium–High | ≈ $2,200–$4,600/unit | 3 years structure |

Advantages are pretty clear: faster schedules, cost control, less waste (offcuts are handled in-factory), and predictable quality. With modular building solutions, you can pilot a single block, scale when funding clears, and still match the aesthetic—yes, external cladding can look sharp. And, I guess this matters more every year, lower embodied carbon versus all-new site-built concrete.

Note: Specify local code alignment—GB 50009 loadings can be mapped to ASCE 7 or Eurocode; your engineer of record should stamp the set.

A coastal clinic deployment finished 28% faster than plan and passed blower-door targets on the first try. A school extension used stacked modules; teachers reported quieter rooms versus portacabins. Small sample size, sure, but it lines up with lab data.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.