What is a flat pack container?

A flat-pack container is a prefabricated modular structure. Itships completely disassembled in a compact package. This 'flat'format minimizes shipping volume significantly. Unliketraditional shipping containers, all components like walls,roof, floor, doors, and windows arrive bundled together.Typically made from durable steel, these units offer robuststorage. They are designed for easy transportation, especiallyto locations with limited access. Brands like ZN House designthem to be man-portable in sections when disassembled. Thesecontainers serve multiple purposes. Common uses include siteoffices, emergency shelters, classrooms, pop-up shops, andsecure storage. They bridge the gap between permanent buildingsand temporary solutions.

GET A QUOTE

How Do Flat-Pack Containers Work?

Flat-pack containers work by enabling simple on-site assembly. Users transport the compactly packed panels and components efficiently. This reduces shipping costs dramatically. Upon delivery, the units are carried to the exact location needed. Assembly requires only basic tools, like a screwdriver and socket set. The process involves fitting the panels together using bolts or similar fasteners. By Incorporating features like high-security locks during assembly, erecting a single unit can take as little as an hour with minimal help. The finished container becomes a strong, sturdy structure. This system allows for quick deployment, easy relocation, and adaptable storage or space solutions. Their modular nature supports both single units and larger complexes.

Key Features: Why Flat-Pack Containers Stand Out

Transport Efficiency

Flat-pack containers maximize logistical advantages. Their disassembled design allows multiple units to fit within a standard shipping container. This slashes transport costs by up to 75% versus pre-built alternatives. Compact packaging enables delivery to sites with restricted access. No heavy lifting equipment is typically needed.

Rapid Assembly

On-site construction is remarkably fast. Two people can assemble one unit in under two hours using basic tools. Components feature pre-installed elements like doors and electrical conduits. Panels connect via galvanized steel frames and high-strength bolts. This simplicity enables immediate use after assembly.

Durability and Adaptability

These structures prioritize longevity. Galvanized steel frames provide corrosion resistance. Integrated insulation (like 50mm EPS) ensures thermal efficiency. Fire-retardant options enhance safety. Powder-coated finishes protect against weathering. Their modular design allows horizontal combinations for larger spaces. Disassembly supports relocation or recycling, reducing waste.

Technical Specifications: Flat-Pack Containers

Flat-pack containers offer standardized dimensions for predictable planning. Common lengths include 2m, 3m, and 4m units. Most models maintain a uniform height and width of approximately 2.1 metres. This modularity allows linking units side-by-side or end-to-end. Users create larger spaces without complex construction.

Structures primarily use galvanized cold-rolled steel. Key frame components feature 2.3mm–2.5mm thickness for structural integrity. Wall and roof panels often integrate 50mm insulation. Options include EPS foam or fire-retardant mineral wool. These materials ensure thermal efficiency and safety compliance.

Assembly relies on precision engineering. Components like columns, roof beams, and bottom beams interlock systematically. Galvanized steel corner fittings (4mm thickness) reinforce joints. Flooring typically combines 18mm OSB-3 boards with PVC or MGO fireproof overlays. Pre-installed UPVC windows (double-glazed) and steel doors simplify installation.

Manufacturers prioritize adaptable configurations. Standard external sizes optimize shipping efficiency. Seven units may fit within a 40HQ container space. Custom lengths up to 9.14 metres accommodate specialized needs. Security enhancements, window types, and interior layouts are adjustable.

|

Attribute

|

20ft Unit

|

6m Unit

|

Notes

|

|

Dimensions

|

|

|

|

|

External (L×W×H)

|

6.06 m × 2.44 m × 2.59 m

|

6.01 m × 2.41 m × 2.49 m

|

Custom lengths to 9.14 m

|

|

Internal (L×W×H)

|

5.90 m × 2.34 m × 2.40 m

|

5.82 m × 2.22 m × 2.25 m

|

Adjustable layouts

|

|

Weight

|

~2,000 kg

|

~1,150 kg

|

Varies by materials

|

|

Key Components

|

|

|

|

|

Frame Material

|

Galvanized steel (2.3–2.5 mm)

|

Galvanized steel (2.3–2.5 mm)

|

Corrosion-resistant

|

|

Wall/Roof Insulation

|

50 mm EPS / mineral wool

|

50 mm EPS

|

Fireretardant options

|

|

Flooring

|

18 mm OSB3 + 2 mm PVC

|

MGO fireproof board

|

Abrasionresistant surface

|

|

Door

|

Galvanized steel

|

Stainless steel (925 × 2035 mm)

|

Deadlock standard

|

|

Window

|

uPVC doubleglazed

|

uPVC tilt & turn

|

Size: 925 × 1100 mm

|

Advantages: Why Choose Flat-Pack Containers?

Flat-pack containers deliver unmatched logistical savings. Their compact transport form reduces shipping costs by up to 75%. Assembly requires minimal labor and no heavy machinery. This cuts construction time by 40% compared to traditional structures.

These units prioritize environmental responsibility. Steel frames are fully recyclable at end-of-life. Insulation often uses recycled EPS or mineral wool. Reusability across multiple projects minimizes waste. Relocation further reduces carbon emissions.

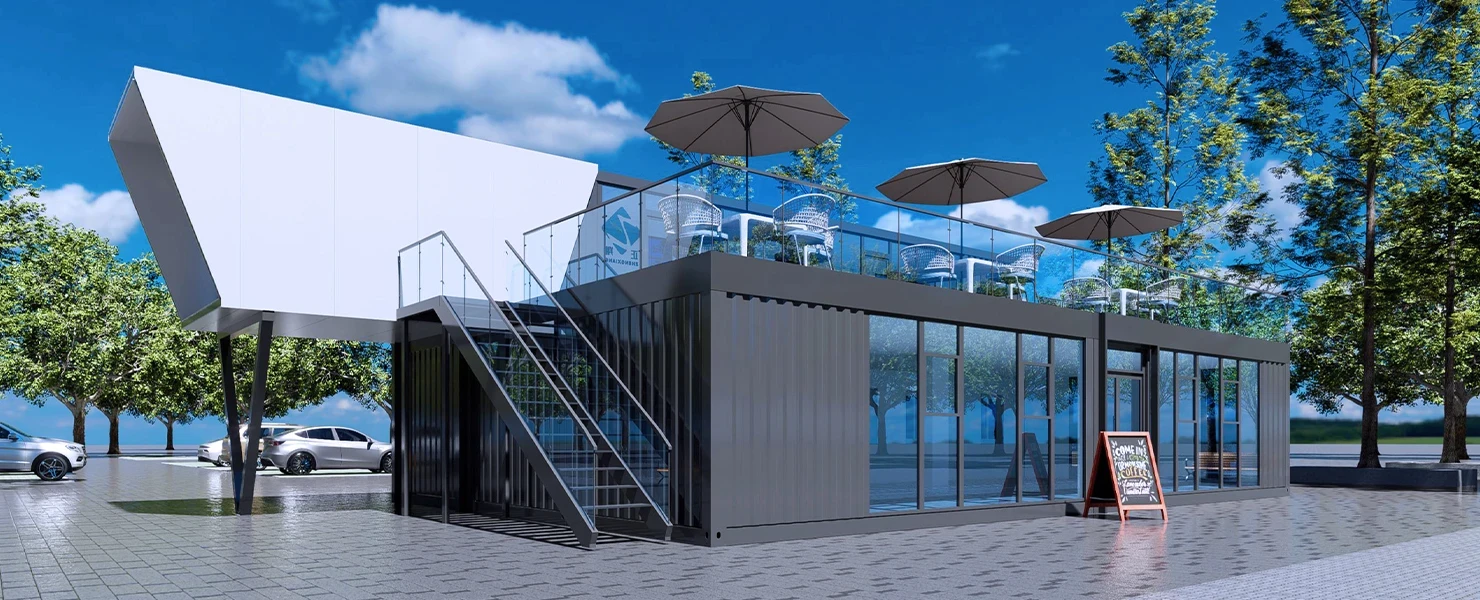

Versatility defines their practical value. Flat-pack containers adapt to commercial, community, or personal needs. Examples include pop-up retail spaces, emergency clinics, or backyard studios. They operate equally well in urban alleys and remote sites.

Customization enhances functionality. Users specify window placements, security upgrades, or insulation types during ordering. Scalability allows effortless expansion. Additional units connect horizontally or vertically as needs evolve.

Durability ensures long-term performance. Galvanized steel resists corrosion in harsh climates. Integrated weatherproofing protects contents reliably. This combination makes flat-pack containers ideal for permanent or temporary solutions.

Implementation Guide: How to Get Started with Flat-Pack Containers

- Step 1: Assess Your Requirements

Determine the size and purpose of your flat-pack container. Measure your available space and usage needs. Small units (e.g., 12m²) work for storage or offices. Larger projects like clinics may require multiple linked containers. Consider site access limitations. Narrow paths or remote locations benefit most from flat-pack designs.

- Step 2: Verify Site and Legal Readiness

Confirm ground conditions are level and stable. Check local regulations for temporary structures. Secure necessary permits early. Ensure truck access for delivery. No cranes are typically needed. Plan clearance for panel transportation to the assembly point.

- Step 3: Select a Reputable Supplier

Prioritize suppliers with:

CE/ISO9001 certifications

Galvanized steel frames (≥2.3mm thickness)

Thermal-break insulation options

Clear assembly manuals or on-site support

Request customization options like window placement or enhanced security during ordering.

- Step 4: Prepare for Assembly

Gather basic tools: socket sets, screwdrivers, and a ladder. Allocate 2–3 workers per unit. Unpack components systematically. Follow the numbered guide included. First, connect floor beams and corner fittings. Then erect wall panels, insert insulation, and secure roof beams. Finally, install doors and windows. Most units assemble in under 3 hours.

- Step 5: Maintain for Longevity

Conduct annual bolt tension checks. Clean PVC floors with mild cleaners. Reapply anti-rust coatings every 3–5 years. For relocation, disassemble panels in reverse order. Store disassembled packs under cover on level ground to prevent moisture damage.

Flat-Pack vs. Traditional Containers: Key Differences

Design Philosophy

Traditional containers prioritize cargo durability during transit. Flat-pack containers focus on human habitation and adaptability. They integrate larger windows and thermal insulation by default. Traditional units require costly retrofits for comfort.

Transport Efficiency

Empty flat-pack containers occupy 80% less space than pre-assembled units. Multiple disassembled bundles fit into one shipping container. Traditional containers move as bulky single structures. This makes flat-packs ideal for seasonal or disaster-response storage.

Cost Structure

- Flat-pack containers reduce expenses in three areas:

- Shipping costs drop by up to 75%

- No crane/heavy machinery rentals

- Zero structural modification needs

- Traditional containers incur extra expenses for transportation.

Installation Flexibility

Flat-pack units assemble in restricted spaces like narrow alleys or remote sites. Two workers can complete assembly with basic tools. Traditional containers demand clear access roads and crane operations. Relocation requires full container transport.

Functional Longevity

Both types use durable steel frames. Flat-pack containers excel in reconfigurability. Panels disassemble for repairs or upgrades. Traditional containers suffer weld fatigue during modifications. Their fixed structure limits layout changes.

Practical Uses for Flat-Pack Containers

Disaster Response

Flat-pack containers enable rapid emergency deployment. Aid agencies establish functional field clinics within 2 hours using these units. Their integrated insulation maintains critical temperatures for medical supplies during infrastructure failures. Compact packaging allows transport via 4x4 vehicles to blocked disaster zones, as demonstrated during Türkiye earthquake relief where units delivered mobile medical stations within 72 hours through debris-filled roads.

Agricultural Mobility

During harvest cycles, flat-pack containers serve as mobile equipment shelters. Farmers position them at field edges for on-demand machinery repairs and seed storage. Galvanized steel frames withstand fertilizer corrosion while PVC flooring resists moisture damage. Units relocate between fields in under 90 minutes – a critical advantage during tight harvest windows.

Event Infrastructure

Event organizers deploy flat-pack containers as modular ticket booths and merchandise stalls. Customizable cutouts accommodate transaction windows and display counters. Units assemble in 15 minutes with pre-installed electrical conduits for POS systems. Post-event, components pack flat for reuse at multiple venues, reducing temporary infrastructure costs by 60% compared to custom builds.

Mining Operations

Flat-pack containers provide essential living solutions for mining teams in isolated locations. These units deploy rapidly where permanent housing is impractical. Workers assemble secure sleeping quarters within hours using basic tools. Insulated walls (50mm EPS) maintain stable temperatures in desert heat or arctic cold.

Each container module serves specific functions according to clients’ needs:

- Sleeping pods with ventilation systems

- Dining units featuring wipe-clean PVC floors

- Medical stations with emergency power hookups

- Recreation spaces for shift rotations

MGO fireproof flooring withstands heavy boot traffic and chemical exposure. Dual-lock steel doors ensure security in unsecured areas. Modular connections create multi-room complexes without construction crews.